Assuming that you are familiar with the fundamental specifications of an ADC and what they mean, the next step is to know your entire signal chain well and then work to fit the ADC to the requirements. After carefully determining signal chain requirements, then select your ADC with the understanding that if the ADC is mismatched, it can report imperfect or misleading data to the controller/processor, and this can be difficult to track down, because the processor will accept what it receives whether the digitized data accurately represents the data or not.

One of the first considerations is what input your ADC has to work with. Sensors can vary widely in the sampling bandwidth; this translates to how often you need to sample the input based on how frequently the data will change. For example, temperature tends to change slowly, so the frequency of sampling can be fairly low in relation to other types of sensors. Touchscreens and accelerometers output data that can change rapidly, however. Find out the range of what’s acceptable in your application. Another parameter is what voltage levels you will be working with from your sensor. The ADC, regardless of type, needs to be able to accept the same voltage range that the sensor provides. The source impedance is a consideration for Successive Approximation (SAR) ADCs (adding a buffer to match impedances can help).

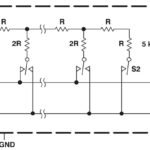

Most SAR ADCs need a device to drive the signal into the SAR converter. If DC specifications are important, and the conversion rate is fairly high, you may need a SAR converter. In any event, the chosen ADC must be given enough time to sample the signal, and sampling time can be affected by the signal source’s impedance going into the ADC. You will need to know if precision is important in your application and if you might want a sample-and-hold feature. SAR and Pipeline ADCs can do this, but not Sigma-Delta. Do you need to convert several signals in phase in relation to each other? Look for this “multi-channel” feature in all three types, otherwise, a multiplexor (with SAR or Sigma-Delta) or a multiple channel ADC will do. How much latency can your system tolerate? How much power can you afford to consume? The datasheet answers all of these questions, but here we compare them all at a high level. What each ADC can provide depends on how they work.

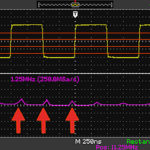

The Sigma-Delta ADC makes use of oversampling signal data and applying digital filters. SARs sample a signal and use an iterative process to converge upon a digital level for each conversion point. Sigma-Deltas have high resolution, are power efficient, and have a relatively low-to-moderate cost. Sigma-Deltas are also lower speed than SARs, in general, and can show cycle-latency. SAR ADCs will have zero-cycle latency, a low latency time, are highly accurate, can be low in power use, and are easier to use than Sigma Delta ADCs. SARS, however, can have lower maximum sample rates. Pipeline ADCs have even faster conversion rates than SAR ADCs, and SARs are faster than Sigma-Deltas. Pipeline ADCs do have the highest speeds and higher bandwidths, but the tradeoffs are lower resolution, higher cost, some latency or delay, and they are power-hungry.

In truth, the SAR and the Sigma Delta ADC are equally viable for some applications, and in other applications, only one or the other will work sufficiently well. You will find in parametric searches, as you narrow down your selection to fit your requirements, that the type of ADC may shift as you filter specs, for instance.

In cases where one could use one or the other, you should know that the Sigma-Delta ADC has more features and is more complex in functions, features, and in PCB layout. Sigma-Deltas have integrated components (e.g., filters, MUXes) that the SAR would need externally. For instance, a Sigma-Delta ADC may accept a differential input directly, whereas a SAR in the same application would require an instrumentation amplifier to convert differential input into a single-ended input. You’ll need to consider anything preceding the SAR for what it will do to your signal, AC or DC. Again, the Sigma-Delta will integrate more functions, reducing component count, but the price is increasing configuration complexity such that some Sigma-Deltas are SoCs of a kind. Integrated functions can include programmable gain amplifiers, input buffers, multiplexers, and more. A SAR ADC tends to require fewer PCB layers to implement than the Sigma-Delta, too. The range of resolutions that SAR ADCs can reach tends toward lower resolutions than the Sigma-Delta can provide, but the trade-off is that SARs are generally faster. There is some overlap in applying Sigma-Deltas or SARs, where your critical specifications will work with either ADC in your application.

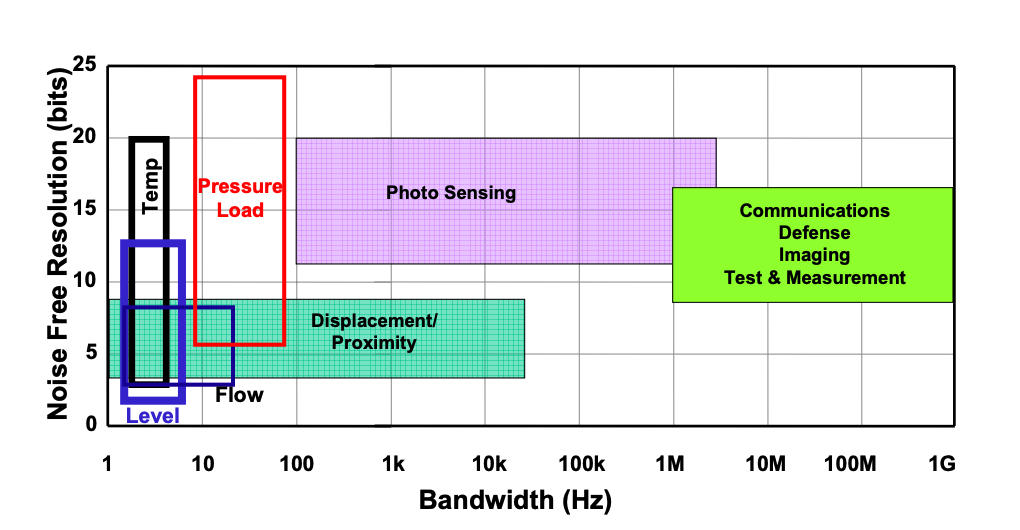

If you need a place to start after having reviewed the fundamentals of ADC specs, try looking at block diagrams on some of the larger semiconductor sites. There you may find a starting point for parameters that experienced designers have recommended for those applications. Sigma-Deltas can be found in precision measurement devices, weigh scales, communications systems, audio, and more. SARs are great general purpose ADCs that you can find in data-loggers, bridge sensors, temperature sensors, among other things.

Pipeline ADCs are found in applications requiring high speeds, such as wireless communications, instrumentation, test and measurement equipment, imaging systems, radar, and data acquisition.