Part 1 of this FAQ examined the underlying context of fluxgate compasses and navigation, as well as the basic principles of the fluxgate design. This part looks at additional fluxgate-compass issues and advances in their implementation.

The fluxgate compass is fairly simple in principle. However, as with all things related to magnetism in general and the Earth’s magnetic field in particular as well as magnetic-related electronics, it’s not that simple. Fortunately, advanced analog ICs combined with processor-based algorithms have significantly improved both performance and usability.

Q: What are some of the issues related to the internal magnetics?

A: As usual, there are issues of temperature-related drift, sensitivity to operating voltages, and “fringing” around the magnetic coils. By using differential circuitry, it is possible to have many of the drift and tolerance issues to self-cancel, and careful construction of the coils can minimize the effects of fringing.

Q: What about external issues?

A: Whenever the Earth’s field is involved, things can get complicated. The magnetic field of the Earth varies in orientation with respect to the poles, as mentioned earlier, so corrections have to be added between what the fluxgate compass senses as magnetic North and true North. Finally, the Earth’s field is not a simple horizontal layer along its surface but dips, and this dip angle increases closer to each pole. There can be cross-coupling between the two field orientations as seen by the compass if the compass platform isn’t perfectly vertical. Therefore, many (but not all) such compasses are mounted in a gimballed arrangement to keep the compass properly oriented, or use some angle-sensing scheme for correction.

Q: What are some advances in sensor technology?

A: The coils and windings have been one of the more costly and bulky components to fabricate. Modern electronics and IC-like processes allow for layering ferromagnetic material on the surface of an IC substrate, with the coils in a planar construction (Figure 1) (Reference 7). Note that similar technology is used for some magnetic-based galvanic isolation components, for both DC and sensor signals.

Q: Is the fluxgate magnetometer the only electronic way to sense magnetic field and direction?

A: No, there are advanced techniques, some of which are suitable only for magnetometers (scalar), while others can also be used for compass (vector) applications. Magnetic sensors can be classified according to whether they measure the total magnetic field or the vector components of the magnetic field. It’s a long list, and many of them are based on atomic-level magnetic principles: optically pumped, nuclear precession, SQUID, Hall-effect, anisotropic magnetoresistance, giant magneto-resistance, magnetic tunnel junctions, giant magnetoimpedance, magnetostrictive/piezoelectric composites, magneto-diode, magneto-transistor, fiber optic, magneto-optic, and MEMS devices.

Q: What are some other advances in fluxgate compasses?

A: First-generation compasses obviously only had an analog output, and each brand (vendor) had its own proprietary output-signal format from the sensing head. Thus, the sensor and readout were linked and had to come from the same source. Modern units now have an industry-standard digital output, so the readout and the sensor are independent, and users can substitute, replace, or update one without affecting the other.

Q: Are there ICs which simplify the coil drive and interface?

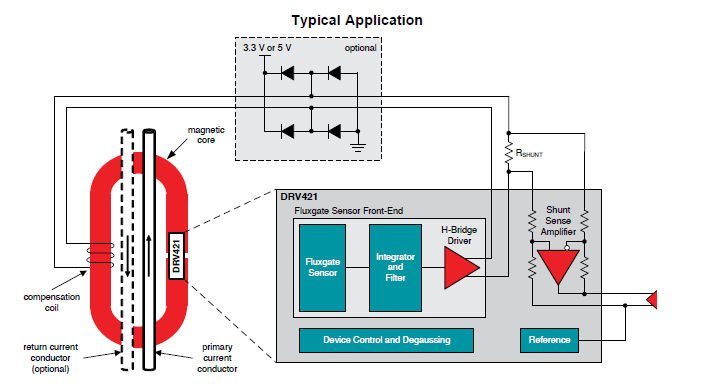

A: Yes, vendors to offer these due to their technical expertise and the opportunity. For example, the Texas Instruments DRV421 is an integrated magnetic fluxgate sensor for closed-loop current sensing, (Figure 2). This IC This 4.00 mm × 4.00 mm device provides both a proprietary integrated fluxgate sensor and the required analog signal conditioning, thus minimizing component count and cost. It also includes provision for incorporating several correction and compensation schemes, including degaussing, and a compensation coil.

Q: How else do today’s sensors and electronics have, which can enhance the performance of a fluxgate compass?

A: The ELECOM compass from TMQ is an example of what can be done, Figure 3. It includes a magnetometer, 3-axis accelerometers, and 3-axis gyro sensors to enable compensation for ship roll and heel. An internal processor handles all needed calculations, including filtering and data reduction, processing the data ten times per second. The unit measures 110 × 73 × 57 mm, operates from a 12-24 VDC supply with under 1-W power requirement, and is waterproof sealed to an IP66 rating.

References from EE World Online

- GPS, Part 1: Basic principles

- GPS, Part 2: Implementation

- How can you improve the next-generation IMU?

- Inertial Measurement Units: The hidden key to Apollo success, now a MEMS device (Part 2)

- Inertial Measurement Units: The hidden key to Apollo success, now a MEMS device (Part 1)

- Precision six-axis inertial measurement unit comes in a small package

- What happens to an MCU if there’s an EMP or Solar Superstorm? Part 1

- The first undersea transatlantic cable: An audacious project that (eventually) succeeded, Part 1

- The first undersea transatlantic cable: An audacious project that (eventually) succeeded, Part 2

- Engineering the atomic submarine, Part 1: One man’s audacity, determination, dedication revolutionized naval reality

- Engineering the atomic submarine, Part 2: One man’s audacity, determination, dedication revolutionized naval reality

Other References

- Ohio History Connection Selections, “Operation of the Flux Gate Compass in B-17 G”

- IEEE Sensors Journal, “Magnetic Sensors and Their Applications,”

- Texas Instruments, SSZY030, “Achieve greater precision, reliability with integrated magnetic sensing technology”

- Imperial College London, Space and Atmospheric Physics, “How a fluxgate works”

- TMQ Europe, “What is an electronic compass with gyro and why do you need one”

- IEEE Transactions on Vehicular Technology, “Automobile navigation using a magnetic flux-gate compass”

- IEEE Transactions on Magnetics, ”Development and Comparative Analysis of Fluxgate Magnetic Sensor Structures in PCB Technology”

- GMW, Magnetometers: A comprehensive guide