by Kishor Kanada, Allied Market Research

Researchers from Somark Innovations launched biocompatible RFID ink that can be used for tattooing laboratory rats and cattle. The ink can be colored or invisible and uses RFID technology with no metals or chips. The usage of chipless RFID in the creation of ink would eliminate the issue of retention of ear tags. Moreover, these inks will not need line of sight for reading them, offering a better alternative to other RFID devices requiring barcodes. The company highlighted that the use of ink would enhance readability.

Mark Pydynowski, the Co-Founder at Somark Innovations, noted that the ink is biocompatible and safe for usage in humans. The RFID tattoos can be used in defense applications such as tracking and rescuing soldiers. During combat, it can be used to identify friends and enemies for the prevention of friendly fire, potentially saving the lives of soldiers. T

Mark Pydynowski, the Co-Founder at Somark Innovations, noted that the ink is biocompatible and safe for usage in humans. The RFID tattoos can be used in defense applications such as tracking and rescuing soldiers. During combat, it can be used to identify friends and enemies for the prevention of friendly fire, potentially saving the lives of soldiers. T

Researchers have been offering innovative technologies and developing chipless RFID with the help of different techniques. Researchers at Universite Grenoble Alpes, Le Laboratoire de Conception et d’Integration des Systemes from Valence, France, launched a chipless RFID system with the help of ultra-wideband (UWB) signals.

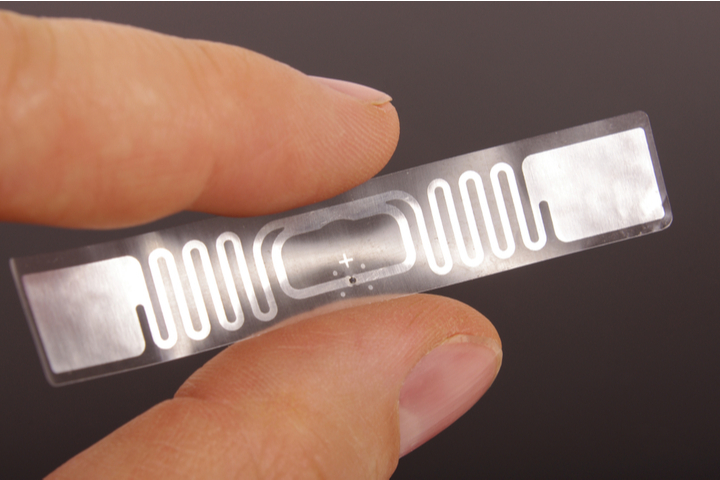

Researchers have also launched time- and frequency-domain chipless RFID tags. In the time-domain chipless RFID tag, a single antenna and transmission line are installed on PCB. With the help of impedance mismatching along the transmission line, coding can be carried out for gaining a unique reflected signal. For a frequency-domain chipless RFID tag, two UWB antennas and a passive filter between them are installed for creating a reflected signal. These two approaches vary in terms of critical parameters such as read time and read range. The tags are designed to extend coverage and flexibility and could lead to cost-effective and efficient wireless solutions.

The development of chipless RFID tags for different applications continues with researchers striving to transform traditional applications. Barcodes printed on products would disappear with the launch of new chipless tags with RFID technology that would be simpler, faster, and cheaper than traditional tracking methods. Researchers from Monash University developed a chipless RFID tag that can be installed on packaging and products such as books, drugs, and others for tracking. The tags can be printed on metals and liquids using an inkjet printer allowing the gag to be read once installed on reflective surfaces such as water bottles and metal cans. This is the first-of-its-kind chipless RFID tag to be printed on plastics and papers.

Dr. Nemai Karmakar, one of the researchers from the team, highlighted that these tags would provide an alternative to the barcode system. This new system is operational at 60 GHz mm-wave signal. This implies that this frequency is smaller than other commercially available tags and can contain considerable data and information. Dr. Karmakar noted that this tag is operational at temperatures above 80 degrees along with cryogenic temperatures.

About the Author

Pratik Kirve is a writer, blogger, and sports enthusiast. He holds a bachelor’s degree in Electronics and Telecommunication Engineering and is currently working as Team Lead – Content Writing at Allied Market Research. He has an avid interest in writing news articles across different verticals. When he is not following updates and trends, he spends his time reading, writing poetry, and playing football. He can be reached at

Pratik Kirve is a writer, blogger, and sports enthusiast. He holds a bachelor’s degree in Electronics and Telecommunication Engineering and is currently working as Team Lead – Content Writing at Allied Market Research. He has an avid interest in writing news articles across different verticals. When he is not following updates and trends, he spends his time reading, writing poetry, and playing football. He can be reached at