Duane Benson, Chief Technology Champion, Screaming Circuits

Have you ever had an LED or other diode placed backwards? PCB assemblers work hard to place every component, from the largest, highest pin-count logic chip, down to the smallest passive components and micro wafer scale BGAs, correctly every single time. A key element of that accuracy is our understanding of your board and the component markings.

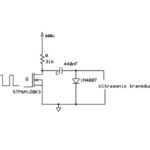

If you use surface mount diodes or LEDs, you probably understand the challenges involved in correctly and consistently indicating diode polarity. LEDs are usually cathode negative, while zeners and uni-directional TVS diodes can be cathode positive. Barrier diodes can be either orientation. It all depends on whether the diode is a rectifier, an LED, a uni-directional TVS, part of a daisy-chain and a host of other considerations.

If you use surface mount diodes or LEDs, you probably understand the challenges involved in correctly and consistently indicating diode polarity. LEDs are usually cathode negative, while zeners and uni-directional TVS diodes can be cathode positive. Barrier diodes can be either orientation. It all depends on whether the diode is a rectifier, an LED, a uni-directional TVS, part of a daisy-chain and a host of other considerations.

When you start looking at the CAD libraries, you not only have all the differences from that manufacturer, you may also have different markation schemes from each CAD package developer and from each library builder.

Guidelines for diode polarity mark silk-screening — the diode symbol, “K” for Cathode or “A” for Anode or. To ensure the best accuracy, we recommend extra care in marking your diodes to remove any ambiguity.

The preferred method is to place the diode schematic symbol in the silk screen. You may also place a “K” for Cathode adjacent to the cathode. “K” is used because “C” could imply that the spot wants a capacitor. An “A” adjacent to the Anode on the board works too, though it’s less commonly used. If you are producing your board without silkscreen, you can put the mark in the copper layer, or submit a clear assembly drawing with the other board files.

Relying on +, – or _ are not definitive in what they indicate and are not recommended. For example, A “+” or “-“ sign isn’t good enough. Because it’s not always true that current flows through a diode from the anode to the cathode. For the common barrier diode, or rectifier, it’s a pretty safe bet. However, with a zener diode, or TVS, it’s not necessarily true. And, that is why marking a diode on your PC board with the plus sign (+) is not good practice.