Part 1 of this FAQ established the context for the quartz crystal as the core of an oscillator whether used as a system clock or as a frequency-setting element in a tuning circuit. This part looks at the achievable performance, the factors that affect it, and what can be done for highest performance.

Q: What levels of performance can be achieved with a standard quartz blank?

A: It depends on many factors including operating frequency, packaging, and temperature changes. In general, temperature is the greatest impediment to the consistent, stable performance of any quartz blank, since it changes the fundamental size and thus resonance of the blank.

Q: Is selection of a crystal and type confusing?

A: It can be. The parameters used to assess the initial performance and their changes will vary with the application, of course. Keep in the that the importance of crystal-based circuits in modern electronics, ranging from consumer products to high-end specialized applications, cannot be overstated. Over the decades there have been countless highly-technical studies of crystal theory and performance. These have been done by vendors university researchers, materials scientists, the National Bureau of Standards and its successor’s organization The National Institute for Standards and Technology, and many other credible individuals and organizations. The result is that the quartz blank and crystal have been studied across almost every possible perspective: size, packaging, electrical connections, material imperfections, temperature, vibration, shock, voltage, circuit, and more.

Q: What level of performance is achievable using a basic, low-end quartz blank?

A: There is no simple, single set of numbers or ranges that represents the performance of a standard crystal, as there as so many variables. The basic “AT-cut” of the crystal results in a unit with stability of between ±50 and ±100 ppm over the -40°C to 85°C range, and about half that over a reduced range of 0°C to 70°C. This is roughly equivalent to a few minutes/moth drift in a time-keeping clock. The more-advanced “SC” cut offers better performance and is roughly twice as stable. A standard crystal used for a digital watch/clock generally has long-term accuracy of about six parts per million (0.0006%) at 31 °C (87.8 °F) and will have ±15 seconds drift per 30 days (less than a half second drift per day) when worn near the skin, which acts as a somewhat-stable temperature environment.

Q: Are those the only choices for crystal cut?

A: Not at all! There are well over a dozen industry-standard, fully defined ways to cut the crystal, each giving different performance along with stability, temperature drift, aging, warm-up time short- and long-term stability and consistency, and phase shift, as well as other performance parameters. As usual, different applications will have different priorities with respect to these factors. The widely used “SC” (stress compensated) cut has performance which is about 5× better than the AT cut but over a more limited temperature range. For example, a battery-powered wall clock will be satisfied with a minute or two per month inaccuracy, while one used for setting the transmit/receive channels on a high-frequency radio needs performance which is 50 to 100 times better.

Q: What else can be done to improve performance?

A: There many ways to deliver an improved crystal blank, and then maintain that performance. One costly but sometimes used technique is to “age” the blank by operating it for six months or a year and thus “working out” its internal stresses, forcing it to become “mature.” Another way is to use the best-available contacts and packaging, such as electro-deposited gold contacts and special vibration-absorbing mounts in a hermetic package.

Q: These are passive techniques, but are there active ones?

A: Yes, there are many. Among the best known are the OCXO, an acronym for “oven-controlled crystal oscillator” and the TXCO, for temperature-compensated crystal oscillator.

Q: How do these work?

A: For the OXCO, the crystal is placed in a temperature-controlled, insulated oven, usually at around 75⁰C, Figure 1. By maintaining this this stable value, many of the short- and long-term drifts stabilized. Obviously, heating the oven takes power which is a drawback in many cases, but a worthwhile tradeoff in others. The OXCO can achieve performance with temperature drift on the order of 0.05 ppm (5 × 10-8) per degree C, which is 50 to 100 times less than a non-OXCO unit; some units perform down to the ppb (billion) range.

Q: What about the TXCO?

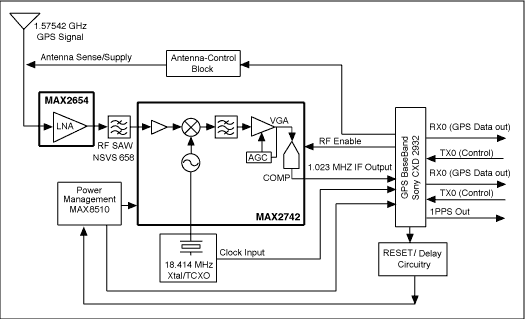

A: The TXCO uses a different active approach, one which uses less power than the OCXO but is not as effective. In the TXCO, additional electronic components are used around the blank which provide opposite temperature coefficients and “pull” the crystal back to the desired value, Figure 2, over a limited range, Figure 3; thus, the temperature-related drift of the blank is largely canceled out. This is less costly and uses less power than the OCXO, but performance is not as good as the OXCO. The compensating components must be carefully selected to have the right value of complementary temperature coefficient, and used is a way that does not degrade the other critical performance parameters of the quartz blank.

Q: Are there other options for improving performance?

A: Yes, there are. For example, the ADTCXO uses an analog circuit with feedback to adjust the oscillator circuit, independent of any associated digital circuitry or processor. The DTCXO has a temperature sensor, and the reading from this sensor goes to an associated processor, which then issues a correction via a D/A converter to induces some compensation factors in the oscillator circuit itself. There are other variations such as the DCXO and MXCO, which use additional software outside of the oscillator to correct and compensate for performance changes due to temperature and other factors.

Q: I need to choose a crystal — what d0 I do?

A: If the application is standard, there is likely an available unit which is already targeted at the situation. For higher-end performance, it makes sense to consult the experts –namely, the vendors of higher-performance units, as they understand the issues and tradeoffs, and what is realistically possible at a given cost and complexity level.

Q: What are my non-quartz options?

A: Some designs can use a lower-performance unit but with regular precision recalibration via the Internet or GPS signals. Another option is a MEMS-based resonator rather than a quartz-based oscillator, which may be a best-fit solution. Extremely high-performance systems may need a rubidium-based atomic clock which offers the highest performance, but at a cost in size, weight, and power; obviously, this is not viable for many applications.

The humble crystal oscillator with a quartz blank often does not get the appreciation or consideration it needs. However, it is a vital part of a successful design, and significant academic and industry effort has been devoted to analyzing, studying, testing, characterizing, and improving it.

References

There are countless technical papers, treatises, application notes, vendor tutorials, and other support material available thus very important topic. Some are highly readable and applicable, while others take a dive deep into basic physics (this does not mean there are of little use; they are very useful). Among the many are these:

- Wikipedia, “Crystal oscillator”

- Bliley Technologies, “Understanding the Types of Crystals Inside of Your Oscillators”

- Bliley Technologies, “Choosing the Best Crystal Oscillator Type for Your Application”

- Bliley Technologies, “The 2 Most Important Qualities of an OCXO”

- Radio-Electronics, “TCXO, Temperature Compensated Crystal Oscillator”

- SiTime Corp, “MEMS-based Silicon Oscillators,”

Also see:

- WHTH, EE World Online, “What is a clock and what are its critical parameters (Part 1)?”

- WHTH, EE World Online, “What is a clock and what are its critical parameters (Part 2)?”

- WHTH, EE World Online, “Chip-scale atomic clocks fit in compact quarters”

For some historical insight, this book is useful in addition to the many brief online articles:

- Richard J. Thompson, Jr., “Crystal Clear: The Struggle for Reliable Communications technology in World War II,” John Wiley & Sons, Inc., ISBN: 978-1-118-10464-4