In Part 1, we looked at the basic principle and function of the solid-state temperature sensors, as well as the first widely available model, the AD590. Part 2 looks at some application considerations.

Q: What are the interface considerations?

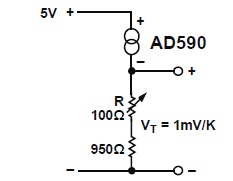

A: A basic solid-state sensor has a PTAT current-only output. This means that the subsequent circuitry, whether all-analog or an analog/digital converter, must be preceded by current-to-voltage (I/V) conversion. This is usually done by having the current pass through a resistor and then using an op amp to amplify and buffer the voltage across this resistor.

Q: What other interface variations of the sensor are available?

A: Vendors have added the I/V function to the sensor IC itself. In addition, they have also built the A/D converter into the sensor die, so the IC is a combination of temperature sensing and digitization. Different models are offered, some with basic digital output (usually 12 bits), as well as different serial formats such as I2C. Doing this reduces overall BOM component count, eases layout, and greatly reduces the potential for unexpected problems in the signal-processing chain due to noise, layout, RFI/EMI, and other factors.

Q: How sensitive is the solid-state sensor to noise pickup?

A: Because it is a low-impedance current loop, noise pickup is far, far less ta it is for a voltage-based sensor. Of course, if the output is transformed into a voltage, then that resultant converted analog output is susceptible to noise pickup. Of course, once the output is digitized, there will be the inherent noise immunity of digital signals.

Q: What about grounding?

A: The sensor is a two-terminal device, and it does not have inherent “ground” or common connection unless its power source is grounded. If this is an issue, an isolated supply can be used.

An alternative is to isolate the output of the I/V converter using an analog isolator. However, in many cases, it is easier and less costly to convert the current output to a voltage, digitize it, and then isolate the serial digitized output by using an optocoupler.

Q: Does a solid-state sensor need adjoining special circuitry, such as the cold-junction compensation (CJC) of the thermocouple?

A: No, as the basic output current is PTAT, there is no need for any sort of compensation circuitry. Ironically, a solid-state sensor is often used for the CJC temperature-sensing function of a thermocouple system.

Q: What accuracy and errors are achievable?

A: As usual, it depends on the vendor, model, and grade of the model. A low-end solid-state sensor can be accurate to ±1°C or ±2°C, while a higher-end one which is additionally rimmed and calibrated at the factory can be accurate to ±0.5°C and even ±0.2°C. Vendor application notes show how analog circuitry — usually a few resistors — can be added to partially compensate for these errors (Figure 1). As an alternative, the user can decide to do calibration in the software.

Accuracy, however, is not the only consideration. The nonlinearity of temperature versus output transfer function is also a concern. A representative figure for this nonlinearity is about ±1°C over range (Figure 2).

As with accuracy, there are some ways that the user compensates, Users can add an active component (op amp) with some trimming resistors to reduce linearity errors (Figure 3 and Figure 4). The user must decide whether it is better to buy a lower-cost, lower-performance sensor and add compensation circuitry for error and nonlinearities, or choose a more costly but higher-performance device.

Q: Can multiple solid-state sensors be used?

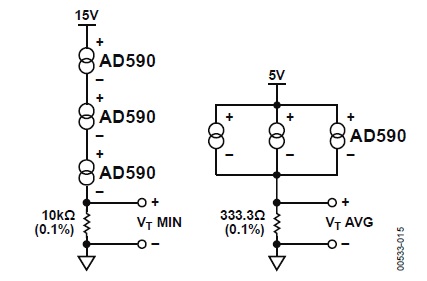

A: Yes, and multiple-sensor configurations can actually be used to advantage. For example, connecting several AD590 units in series results in a current value representing the minimum of all the sensed temperatures; using the sensors in parallel yields the average of the sensed temperatures (Figure 5).

Q: Can solid-state sensors be multiplexed? If so, how?

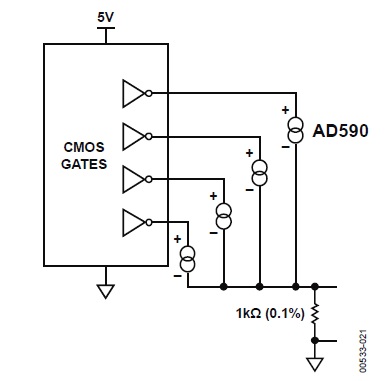

A: It is relatively easy to multiplex solid-state sensors; one approach is shown in Figure 6. Any AD590 device which is connected to a logic high then passes a signal current through the current-measuring circuitry (note the single resistor used for the front end of I/V conversion), while those connected to a logic low pass insignificant current.

Q: What about packaging?

A: To meet temperature, performance, and cost objectives, solid-sate sensors are available in a range of standard-IC packages. The basic two-terminal sensor is offered in a two-lead flatpack, four-lead LFCSP, three-lead transistor TO-52, and eight-lead SOIC housings, among others. Note that for packages with more than two leads, only two leads are active, while the rest are “not connected” but present so the package meets industry standards.

Q: Finally, what about cost and availability?

A: Obviously, this varies based on vendor, model, grade, package, and quantity. A basic solid-state sensor can be well under a dollar for the lowest grade to about ten dollars for the highest grade; those with integral I/V-converter and A/D-converter functions cost more, of course. Due to the popularity of solid-state sensors, vendors offer both proprietary units as well as second- and alternate-source versions., so users have a wide array of choices.