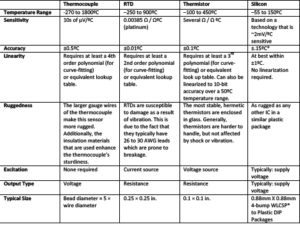

Temperature doesn’t change very quickly, and temperature sensors match that characteristic. Environmental temperature changes are generally slow, on the order of less than 0.1 sec/°C. Typical temperature sensors used in circuits are resistance temperature devices (RTDs), thermocouples, thermistors or integrated silicon sensors. Trade-offs amongst these devices include cost, cost to operate, response time, noise immunity, operating temperature range, and stability. Stable devices will produce less output signal drift over time, which reduces the need for repeat calibrations.[i]

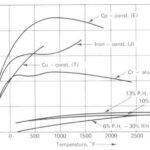

Thermocouples are inexpensive, rugged, stable, operate over a wide temperature range, and are relatively linear over a wide range but deviate significantly at extremely cold or hot temperatures. Thermocouples have two different types of conducting wires that form electrical junctions at two different temperatures – one junction is at a reference temperature; the other junction is at the temperature that’s being measured.

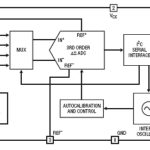

A thermocouple generates a voltage that correlates to temperature, a result of something called the Seebeck effect. Thermocouples require a controller with a look-up table of thermoelectric voltages and coefficients to generate a linear signal. There are standard types of thermocouples that have known curves, and curve-fitting coefficients are available from the National Institute of Standards and Technology (NIST).

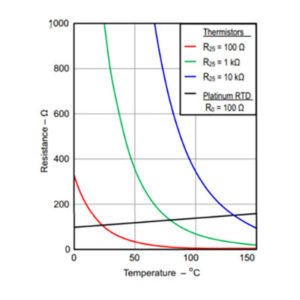

RTD elements change resistance values with changes in temperature. RTDs are wire-wound for high-temperature applications and can be fragile. RTDs for low-temperature applications are thin-film (flat-film) serpentine elements that are mounted in a substrate. They are offered in several metals, including platinum, copper, nickel, and nickel-iron. The platinum RTD is the most accurate sensor of all types of sensors covered in this article and covers a broad temperature range, is stable, demonstrates good noise immunity, has excellent repeatability and linearity, yet is the most expensive option.

However, a stable reference current must be provided to measure the resistance value of the RTD element. RTDs require a look-up table or equation to interpret temperature values in relation to the output.

Thermistors are temperature sensitive resistors known for a rapid response. Like RTDs, thermistors also change in resistance with changes in temperature and require excitation. However, the elements are made of ceramic or polymer instead of metal. Thermistors generally have higher resistance values versus RTDs and therefore operate with lower reference currents and thus lower energy consumption.

With different materials, thermistors can achieve greater precision, albeit over a limited temperature range. Thermistors require a look-up table or equation to interpret temperature values in relation to the output. Thermistors are also used for circuit protection as current limiters and as heating elements.

Semiconductor temperature sensors are based on the temperature-dependent relationship between the base-emitter voltage and the collector current of a bipolar junction transistor (BJT). Semiconductor-based temperature sensors are easily integrated within semiconductor ICs, but they are slow to respond to fast temperature changes. The size of semiconductor sensors has decreased such that they are a competitive choice to RTDs for some applications.i

References:

[i] Kuglestadt, Thomas. Semiconductor Temperature Sensors Challenge Precision RTDs and Thermistors in Building Automation. Apr. 2015. Dallas, Texas.

[ii] Bonnie Baker, A Baker’s dozen: real analog solutions for digital designers (Amsterdam: Elsevier/Newes, 2005).