pH probes, with their bipolar voltage outputs and high output impedance, need signal conditioning through an analog front end to make them compatible with measurement circuits such as A/D converters.

By Marian Hryntsiv, Renesas Electronics

People who work in healthcare, food and beverage, water treatment, chemical processing, agriculture, and environmental monitoring rely on pH meters to make decisions about hydrogen-ion activity (pH) in water-based solutions. The main component of any pH meter is a pH electrode, a pH probe. These probes need analog circuits to condition their high output impedance to A/D converters and make the signals unipolar.

A pH probe (Figure 1) generates a voltage based on the activity of hydrogen ions (H+). A voltage arises when two liquids with contrasting pH values meet on opposing sides of a thin glass membrane. The pH electrode operates as a passive sensor without the need for external excitation voltage or current. Categorized as a bipolar sensor due to its capacity to yield an output that fluctuates both above and below the reference point, a pH probe generates a voltage output that’s linear with respect to the pH level of the solution under examination. The pH probe’s source impedance typically ranges from roughly 10 MΩ to 1000 MΩ due to the substantial resistance of the thin glass bulb.

To design a conditioning circuit for the pH probe’s output signal, you need to understand its characteristics. Firstly, because the pH electrode generates a bipolar signal and many applications operate on a single power supply, the analog front end must perform signal level shifting. Secondly, given the high impedance of the electrode, the circuit needs a high-input impedance buffer. Lastly, to account for variations in the electrode’s sensitivity to temperature, you need to measure the solution’s temperature. Figure 2 shows a general schematic of the pH probe analog signal-conditioning circuit. Here’s how to use the AnalogPAK SLG47004 as an analog front-end for a pH probe.

The circuit uses a 250 MΩ pH electrode. As a rule, operational amplifiers with a tiny bias current (about tens of femtoamperes or even less) are used as buffer amplifiers for such sensors. Unfortunately, such precise amplifiers have considerable voltage-offset error. A trimming function compensates for the offset error caused by bias current.

The transfer function of the pH electrode is:

Where:

pH(X) is pH of unknown solution(X)

pH(S) is pH of standard solution = 7

ES is the electric potential at the reference or standard electrode.

EX is the electric potential at the pH-measuring electrode.

F is the Faraday constant = 9.6485309×104 C mol-1

R is the universal gas constant = 8.314510 J K-1 mol-1

T is the water solution temperature in Kelvin.

Figure 3 shows the pH scale based on the transfer function for T = 25°С.

Circuit design

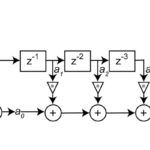

Figure 4 shows a general schematic of the analog front-end for the pH probe based on the SLG47004. Figure 5 shows an internal design of the signal-conditioning circuit for the pH electrode in the GreenPAK Designer software. The “Power Up” button applies power to the circuit. The delay macrocell DLY4 works as a debounce filter to eliminate switch bouncing. DFF2 latches the voltage level and toggles it each time the button is pressed, transitioning between working mode and sleep mode.

As evident from the pH scale, the signal from the electrode can reach down to -411 mV. Therefore, a 512-mV offset voltage is sufficient to ensure that the signal from the electrode is always positive. Amplifier OpAmp0 provides this 512-mV offset voltage, achieved through a high-drive voltage reference macrocell called HD Buffer that uses the shared voltage reference source VREF OpAmp0. The HD Buffer output produces an accurate 1.024 V, which is then halved by a 51 kΩ resistor divider to yield 512 mV. Amplifier OpAmp0 is configured for unity gain and applies this 512-mV voltage to bias the reference electrode of the pH electrode, maintaining a low impedance. Consequently, the pH-measuring electrode produces a voltage superimposed upon this 512-mV bias voltage. Essentially, the circuit transforms the bipolar pH-electrode signal into a unipolar signal suitable for use in a single-supply system.

The second amplifier, OpAmp1, operates as a unity-gain buffer for the pH electrode’s output. This high-input-impedance buffer between the pH electrode and the measurement device ensures the circuit’s compatibility with a wide range of measurement instruments, including those with lower input impedance. In most applications, the voltage output from the pH electrode is sufficiently high for direct use, eliminating the need for extra amplification. If, however, you need amplification, you can adjust this circuit by introducing gain resistors to OpAmp1.

The SLG47004 has a built-in temperature sensor to measure the solution’s temperature, allowing for adjustments that compensate for sensitivity variations due to temperature.

Auto-trim

When using a pH meter for the first time, you must calibrate it. There is a special calibration button that initiates this process. You should also perform periodic calibrations. For example, if the pH meter operates continuously, it should be calibrated after a week of operation.

For calibration, the SLG47004 has an Auto-Trim function. The key macrocell responsible for the Auto-Trim is the Chopper Analog Comparator. The Chopper ACMP uses OpAmp1’s output signal as voltage feedback and compares it with the desired 512 mV. During calibration, the pH electrode should be immersed in a buffer solution with a neutral (7.0) pH level. Buffer solutions maintain a constant pH value when small amounts of and acid or base are added to them. In this scenario, OpAmp1’s output voltage should match 512 mV because the voltage at the pH electrode’s output is 0 mV. If these two voltages do not match, the chopper comparator adjusts the rheostat’s RH0 resistance by controlling the Up/Down and CLK rheostat inputs. At the end of the Auto-Trim process, the voltage at OpAmp1’s output will be 512 mV.

Use the Calibrate button to start the calibration. The delay macrocell DLY3 functions as a debounce filter to eliminate switch bouncing. The CNT/DLY1 works as a one-shot, creating a 250 ms pulse because the maximum duration of the Auto-Trim process is calculated as rheostat code divided by the clock rate, which is 512/2048 = 250 ms. The trim process begins with the rising edge on the Set input of Rheostat 0. After receiving a ready signal from the analog blocks, the clock pulses for the internal counter of the rheostat are enabled. The counter counts up or down depending on the level at the Up/Down input. Figure 6 shows the auto-trim waveforms.

The internal counter stores the rheostat’s current value, which you can program into the GreenPAK’s MTP NVM by setting logic high at the program input. This input is rising-edge sensitive and has no effect when the Auto-Trim process is active. To meet these requirements, a falling-edge detector generates a short pulse on the falling edge of the pulse in Figure 6. This ensures that programming takes place after the Auto-Trim is completed. The SLG47004’s ability to program and store rheostat values is useful in this situation. That’s because it allows for the use of the stored rheostat value each time the pH meter is turned on, without the need to perform the Auto-Trim every time.

Testing

The system using this circuit was initially calibrated using the Auto-Trim function with a buffer liquid of pH 7 (neutral). That produced the 512-mV output shown in Figure 6. To test the meter readings, we then used buffer liquid with a pH value of 4, resulting in a measured voltage of 676 mV. Therefore, 676 – 512 = 164 mV is the voltage attributed to the pH electrode. Because the electrode’s sensitivity at 25°C is 59.16 mV, then 164/59.16 = 2.77. Because neutral liquid has a pH value of 7, the measured liquid’s pH is 7 – 2.77 = 4.23 pH.

Considering that the buffer fluid may have some error (often indicated on the solution bottle), the electrode has its offset error, and no temperature compensation was applied, the results are reasonably acceptable. Test results for distilled water (pH = 7), diluted water with acid (pH = 4), and diluted water with base (pH = 11) are shown in Figure 7.

Conclusion

When used in analog applications, the SLG47004 lets you include an op-amp with a very low bias current or offset voltage. The SLG47004’s Auto-Trim function minimizes bias error, something needed for applications such as pH probe signal conditioning. The SLG47004’s in-system programmability lets you place an unprogrammed IC onto the PCB and modify its configuration or lets you add new functions during the production phase by programming the multi-time programmable memory.

You can download our free GreenPAK Designer software to open the .aap file and view the proposed circuit design. Use the GreenPAK development tools to freeze the design into your own custom IC.