The spring pin socket for BGA529 features a short spring pin, 1.65mm compressed height, and provides a high electrical bandwidth of 60 GHz with an inductance of 0.3nH along with 2A continuous current carrying capacity. The clamshell lid with compression screw allows gradual pressure to BGA with easy chip replacement functionality.

PCB design

Color-keyed thru-hole mount test points

Identification of test points in high-density PCB packages is the key to greater PCB production testing and service troubleshooting. Keystone Electronics has developed a full line of thru-hole mount test points with a color-keyed insulator base for visibility and quick identification to replace wire-wrap posts and turret terminals. The Keystone wire loop THM Test Points […]

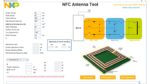

If you are working with antennas, here are some tools to consider, Part 1

Antenna design and integration is an important activity for 5G telephony, wireless Internet of Things (IoT) nodes, Wi-Fi networks, near-field, and satellite communications, and various other applications. Without robust antenna designs and solid system integration, the performance of those applications can be severely compromised. Balancing the needs for efficiency, gain, bandwidth, pattern characteristics, and decreased […]

Miniature SMT test point

A miniature SMT test point featuring a symmetrical flat-wire design to test PCBs efficiently and safely is one of many items available in the Keystone Electronics Corp. test points selection. This latest “Mini-pad” version enables high-strength, test point-to-PCB bonding, with a minimal footprint. In addition to cost-savings, this low-profile entry accepts a variety of gripping […]

PCB design best practices for ECAD/MCAD collaboration

By Alex Grange, Siemens EDA As designs grow in scope and complexity, collaboration between the electronic and mechanical domains is even more important. For example, as PCB designs face tighter requirements, problems resulting from electromechanical interference are becoming more common. Handling these problems across disciplines requires constant collaboration and synchronized data. What isn’t working today […]

Why should you be using rigid-flex PCBs rather than flex PCBs in your next project?

by Ken Ghadia, Sales Engineer, TechnoTronix Rigid-flex or rigid-flexible PCBs are the preferred interconnection circuits in today’s electronics. They have simplified the PCB assembly with superior mechanical stability and electrical reliability features. The driving factors for their popularity are reduced product weight, compact packaging, and quick assembly. Rigid-flex PCBs were designed primarily for critical interconnections in […]

How cloud PCB manufacturing is unlocking new doors for the PCB industry

By Suresh Patel, Sales Engineer, Mer-Mar Electronics Cloud manufacturing is an AI-based, advanced manufacturing approach that streamlines different production processes, integrates stand-alone functions, and automates all manual tasks through remote-hosted software. It is also known as digital manufacturing or Manufacturing as a Service (MaaS). This model aims at continual improvement of the manufacturing process with […]

Bare element shunt resistors help lower thermal stress of PCBs

Current sensing for motor control applications often requires robust current handling and the lowest possible PCB temperatures. Unfortunately, high current or overload current handling typically means higher PCB temperatures. One cost-effective and popular solution to these requirements is a raised bare element sense resistor. The elevated bare element yields PCB temperatures of 30% to 40% […]

Electrostatic shielding now available for high-voltage reed relays

Pickering Electronics now offers optional electrostatic shielding for its 10kV stand-off Series 67/68 SIL/SIP reed relay families. Electrostatic screening protects against noise that can otherwise occur between the coil drive and high-voltage circuits. This new screening is in addition to Pickering’s internal mu-metal screen which eliminates magnetic interaction when devices are closely stacked. Series […]

Why should you boundary-scan all your manufactured PCBs?

By Suresh Patel, Sales Engineer, Mer-Mar Electronics The Boundary-scan, aka JTAG (Joint Test Action Group), is the IEEE 1149.1 standard used to verify and test Integrated Circuits (IC) interconnections on the PCBs. Using the boundary scan in PCB production will effectively reduce manufacturing costs, accelerate test automation, and improve PCB quality with better fault coverage. […]